Armide report June 11th 2018

Armide report June 11th 2018

Photos of recent works undertaken

-

Checking the topsides for fairness

-

![56-02]()

Capping rail at the stem with hawse pipes dry fitted for checks

-

![56-03]()

Hawse pipes dry fitted with cove line end details

-

![56-04]()

Hawse pipes dry fitted with cove line end details

-

![56-06]()

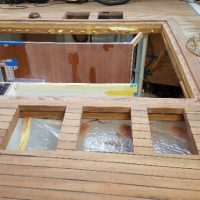

Openings in the deck at the half skylights alongside the doghouse

-

![56-08]()

Six bronze deck bollards being drilled and prepared for installation

-

![56-05]()

Lifting the varnished doghouse onto the deck for final installation

-

![56-07]()

Openings in the deck at the half skylights alongside the doghouse

-

![56-10]()

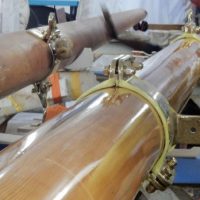

Copper sheathing on the rudder at the propeller cut-out

-

![56-09]()

Copper sheathing on the rudder at the propeller cut-out

-

![56-16]()

Drilling the capping rail at each chain-plate for the rigging screws

-

![56-15]()

Drilling the capping rail at each chain-plate for the rigging screws

-

![56-14]()

Carving under way on the owners’ motif that will be inserted flush into the transom

-

![56-12]()

Copper sheathing on the stern post and inside the lower rudder trunk

-

![56-11]()

Copper sheathing on the stern post

-

![56-13]()

Teak name board for inserting flush into the transom

-

![56-17]()

Trial fit of rigging screws through the capping rail; bulwark lighting cables visible also.

-

![56-21]()

Mock-up of the octagonal box that will be on top of the bronze compass pedestal

-

![56-19]()

Fabrication underway of the low deck boxes either side of the helmsman’s seat

-

![56-20]()

Fabrication underway of the low deck boxes either side of the helmsman’s seat

-

![56-18]()

Detail of aft face of deck bench at the cockpit area

-

![56-22]()

Mock-up of the octagonal box with engine control lever & bow thruster joystick

-

![56-23]()

Installation of bronze mast fittings

-

![56-24]()

Installation of bronze mast fittings

-

![56-26]()

Installation of bronze mast fittings

-

![56-28]()

Porthole outer ring installed prior to fairing and final topcoat painting

-

![56-25]()

Installation of bronze mast fittings

-

![56-27]()

Drilling off the whisker shroud hull fittings

-

![56-29]()

The completed carving with the owners’ motif, ready for letting into the transom.

Leave a Reply

You must be logged in to post a comment.